EPDM Bonded Washer: Features, Benefits, and Industry Applications

An EPDM Bonded Washer, made from a durable combination of a metal ring and EPDM rubber, provides exceptional sealing and weatherproofing capabilities. It is a trusted solution across industries, including construction, machinery, and automotive, particularly for waterproofing roofs and securing screw connections. The EPDM Bonded Washer Series, offered by KCS Enterprise Company Limited, delivers a versatile range of solutions designed to meet diverse sealing needs.

How EPDM Rubber Enhances Bonded Washers

The outstanding performance of the EPDM Bonded Washer comes from the EPDM rubber used in its design. EPDM rubber is a synthetic elastomer known for its excellent durability and sealing properties. Key features of EPDM rubber include:

- UV and Ozone Resistance: Ensures long-lasting performance in outdoor applications, even under intense sunlight and ozone exposure.

- Temperature Resilience: Maintains elasticity and functionality across a wide temperature range, from -40°C to 150°C.

- Chemical Resistance: Effectively resists a variety of chemicals, making it ideal for industrial environments.

- Abrasion Resistance: Reduces wear and tear in demanding conditions, ensuring the washer's durability over time.

When combined with a sturdy metal ring, these properties make EPDM Bonded Washers ideal for applications requiring secure sealing and reliable performance.

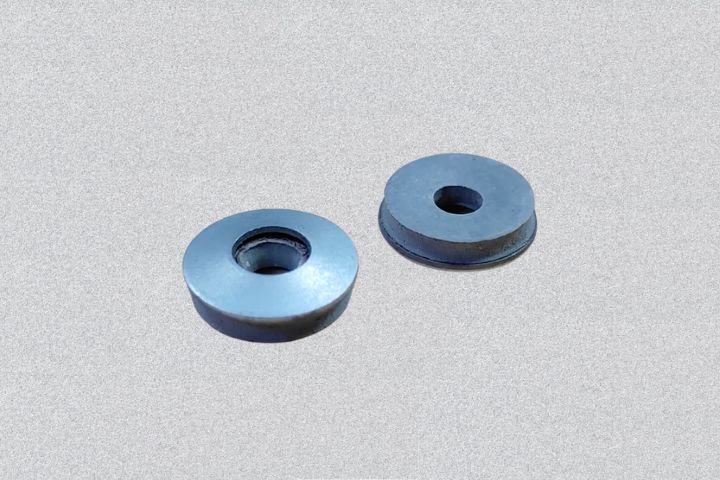

Structure and Function of EPDM Bonded Washers

The EPDM Bonded Washer Series is composed of two primary components:

- Metal Ring: Made from galvanized steel, stainless steel, or aluminum, the metal ring provides mechanical strength and ensures stability under high-pressure conditions.

- EPDM Rubber: The rubber component creates a secure, weatherproof seal that prevents leaks of water, gas, oil, and other substances.

This structure offers several benefits:

- Reliable Sealing: Ensures a tight seal even in harsh environments.

- Enhanced Durability: Resists deformation or breaking under pressure and extreme temperatures.

- Customizable Design: Available in various sizes, materials, and configurations to meet specific requirements.

Applications

EPDM bonded washers are indispensable in many industries, including:

- Construction: Used in roofing and cladding systems to seal screw connections and prevent water ingress, protecting structural integrity

- Automotive: Ensures leak-proof seals in vehicle components, even under extreme operating conditions.

- Machinery: Prevents leaks and maintains system pressure in hydraulic, pneumatic, and other mechanical systems.

Why Choose the Bonded Washer Series?

The EPDM Bonded Washer Series from KCS Enterprise Company Limited is engineered for reliability and precision. Key advantages include:

- Versatility: Suitable for a wide range of sealing applications across multiple industries.

- Custom Solutions: Options for tailored dimensions, materials, and coatings to fit specific project needs.

- Long-Term Performance: Designed to withstand challenging environments, minimizing the need for replacements.