What is a bonded washer

A bonded washer is a critical component in many industrial applications, designed to provide a reliable seal between two surfaces. This simple yet effective device consists of a metal washer with a rubber seal bonded to it, ensuring that fluids or gases are contained within the designated area. Whether in plumbing, automotive, or construction industries, bonded washers are essential for preventing leaks and maintaining the integrity of mechanical assemblies.

This article will focus on explaining the structure, types, benefits, and broad applications of bonded washers, helping you make informed decisions when choosing and using this essential component.

How Bonded Washers Are Constructed

Bonded washers are composed of two key elements: a metal washer and a rubber seal. The metal part is typically made from materials like stainless steel, brass, or galvanized steel, providing structural support and resistance to wear and tear. The rubber seal, often made from materials like neoprene or EPDM, is bonded to the metal washer, creating a tight, durable seal.

This combination allows the washer to withstand various environmental conditions, including high pressure, extreme temperatures, and exposure to chemicals.

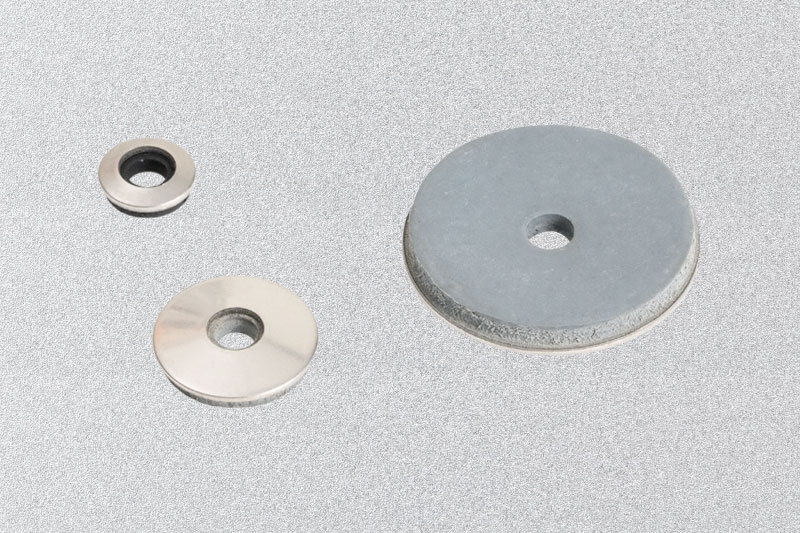

Types of Bonded Washers

Bonded washers come in different types, each designed for specific applications:

- Standard Bonded Washers: These are general-purpose washers used in a wide range of sealing applications, providing effective leak prevention and protection against corrosion.

- High-Pressure Bonded Washers: Specifically designed for high-pressure environments, these washers are made from stronger materials and are engineered to handle intense pressure without compromising the seal.

- Customized Bonded Washers:For unique applications, custom-made bonded washers can be manufactured to meet specific size, material, and performance requirements.

Key Benefits of Using Bonded Washers

Bonded washers offer several significant advantages:

- Leak Prevention: The primary function of a bonded washer is to prevent leaks by providing a secure seal. The rubber component compresses against the surfaces it is installed between, creating a barrier that fluids or gases cannot pass through.

- Corrosion Resistance: Depending on the materials used, bonded washers can offer excellent resistance to corrosion, making them suitable for use in harsh environments where exposure to moisture or chemicals is a concern.

- Vibration Dampening: The rubber seal in a bonded washer also acts as a vibration dampener, absorbing shocks and reducing the risk of loosening bolts or screws in mechanical assemblies.

Common Applications of Bonded Washers

Bonded washers are used across various industries due to their versatility and effectiveness:

- Plumbing: n plumbing systems, bonded washers are vital for preventing leaks at pipe joints and connections. Their ability to create a watertight seal ensures that fluids remain within the system.

- Automotive: In the automotive industry, bonded washers are commonly used in engines, transmissions, and brake systems to seal oil, fuel, and other critical fluids, preventing leaks that could lead to system failures.

- Construction and Roofing: Bonded washers are often employed in construction and roofing applications to provide weatherproof seals around fasteners, ensuring that buildings remain watertight and resistant to the elements.

Selecting the Right Bonded Washer

When choosing a bonded washer, several factors need to be considered to ensure optimal performance:

- Material Considerations: The choice of materials for the washer and the seal should be based on the environment in which the washer will be used. For example, stainless steel and EPDM rubber are ideal for corrosive environments.

- Size and Fit: Selecting the correct size and fit is crucial for ensuring that the bonded washer can provide an effective seal. It is essential to match the washer’s dimensions to the specific requirements of the application.

- Load and Pressure Specifications: The bonded washer must be able to withstand the load and pressure exerted on it during use. Choosing a washer that meets or exceeds these specifications is vital for long-term reliability.

Bonded washers play a crucial role in various industrial applications by providing reliable sealing solutions. Their ability to prevent leaks, resist corrosion, and absorb vibrations makes them indispensable in industries ranging from plumbing to automotive and construction. When selecting a bonded washer, it is essential to consider factors such as material compatibility, size, and pressure requirements to ensure that the washer performs effectively under the intended conditions.

Established in 1983, KCS Enterprise Company Limited has set the benchmark as the foremost bonded washer manufacturer and one of the most reliable bonded washer suppliers in Taiwan. KCS offers the Bonded® Washer series, CR Washer, Bonded Saddle® Gasket series, Umbrella (BAZ) Washer series, and more.

With over 40 years of experience in producing the highest quality Bonded® Washers and Rubber Gaskets, we ensure that our products meet the strictest industry standards.

Ready to enhance your projects with our top-tier sealing solutions? Contact us today to discover how KCS can provide the perfect washers and gaskets tailored to your needs.